MicroAlgae based Biorefinery as a business answer to climate challenges

With the world population constantly growing, chemical, energy, and fuel industries among others are all seeking for sustainable feedstocks. MicroAlgae Biorefinery offers an innovative and sustainable technology and B2B business model, which makes large-scale production of algae biomass possible based on waste streams and use of CO₂. Apart from the economic benefits of the solution, it answers the present climate challenge by delivering energy savings, closed loop production, enhanced resource recovery and the production of CO₂ neutral feedstock for many applications.

M

A

B

2.0

About

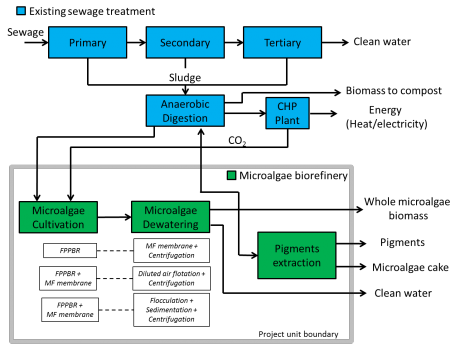

The Climate-KIC supported Microalgae Biorefinery 2.0 (MAB 2.0) project aims to demonstrate two breakthrough technological and commercial concepts to increase B2B cooperation, sustainable production of feedstocks and resource efficiency. The solution turns certain waste water treatment effluent into added value algae biomass by recovering of nutrients, capturing CO2 of biogas plant and embedding sunshine. Through B2B business model the project will also secure link to different algae processors to harvest the value.

Integration

Integration of algae technology into waste water treatment plants can enhance water quality, build green image and improve economics.

Biorefinery

Algae biomass and thus waste water can be turned into high added value and biobased products.

The project will target waste water treatment companies demanding a solution that can make their operation more sustainable, efficient, reduce emissions and provide additional revenues at the same time. The project will result in a commercial offer for the waste water treatment sector in order to turn certain streams of waste water treatment into algae biomass while removing the excess nutrients of waste water effluent. Also, preliminary results show a demand for algae-based compounds hence the project creates a B2B link between waste water treatment companies and algae processors. The figure shows the technology focus of the project.

Business offer

Reducing load – saving future

We offer waste water treatment improvement by installing algae reactors in industrial scale reducing nitrogen and phosphate loads and carbon emission while generating additional revenue streams.

For waste water treatment companies and professionals

For algae processors

If you are a representative or have expertise in waste water treatment and interested how to reduce the environmental load, to generate additional revenue, and also build a sustainable company and green image – then contact us since we would like to know better your demand and preferences in giving place to innovations. As our business model is based on B2B cooperation you don’t need to worry on how to use algae biomass, we will take care of it. Nevertheless, local biorefinery companies are also welcome. So why not give a try?

If you are a representative or have technology to process algae into a variety of added value products and look for algae biomass in scale and reasonable price then contact us we would like to learn more about your expectations towards algae raw materials.

Expertise

Microalgae are microscopic species growing in freshwater or in marine environment. As being able to photosynthesize these small creatures are able to turn nutrients and CO2 into biomass and other valuable compounds - just like plants. There is a wide variety of microalgae species making it possible to find the best one for different feedstocks (such as streams of waste water treatment) and for the most valuable algae-based product. Depending on the strain and environmental conditions, microalgae can accumulate different compounds, such as lipids, pigments and so on. If cultivated perfectly algae production can deliver high biomass yields per area, and thus become a target biomass for biorefinery operations.

Partners of the project have developed different demonstration units for algae cultivation and harvest. The gathered expertise and complementary knowledge secure the right choice of technology for integration into waste water treatment.

Budapest Sewage Works

Budapest Sewage Works is the largest environmental management company of Hungary and is always open to apply novel sustainable solutions and find a business case for them. Based on this mission the company has already invested in a pilot scale algae production unit at the North Budapest Waste Water Treatment plant.

WUR - Algaeparc

The Wageningen University Research AlgaePARC is a large multidisciplinary research program which integrates the entire microalgal process chain. The Wageningen demonstration area operates with 4 different pilot scale production systems: Horizontal and Stacked Tubular Photobioreactors, High Rate Algal Pond and Flat Panel reactor. This site offers numerous possibilities for research, training and education as well as technical visits.

University of Valencia and Polytechnic University of Valencia

The Valencian universities have been developing an Innovative Membrane PhotoBioreactor providing efficient cell growth and nutrient removal combined with harvest. The patenting of this technology is in progress. A pilot scale unit is of this solutions is in operation at the Valencia urban waste water treatment plant.

INRA LBE

INRA-LBE has also focused part of its activity on macro- and micro-algae production combined with bioenergy production. At the Narbonne location in France various systems are operational, ranging from reactors with a capacity of a few liters to a 28 m3 raceway pond.

Climate-KIC Innovation Framework

The commercialization pathway of the project is provided by the Climate-KIC framework securing the effective implementation and control, as well as bringing forward business impact and mindset. The project is organized according to the Climate-KIC Innovation Framework principles and thus follows the below 3 stages also explained in the video. Climate-KIC is the EU’s main climate innovation initiative focusing on bringing ideas to the market in order to tackle climate change. Climate-KIC is one of the Knowledge and Innovation Communities (KICs) created in 2010 by the European Institute of Innovation and Technology (EIT), the EU body tasked with creating sustainable European growth while dealing with the global challenges of our time.

Proof-of-Concept

Proof-of-Concept assures the stakeholders of the Innovation Opportunity that the potential innovation is tested and the “market” demand can, in theory, be met.

Demonstration

Demonstrator shows that the potential innovation can be applied in a real environment and can deliver the impact.

"Market"

Market Readiness optimises and scales the actual innovation to take it to “market”.

Partners

The project builds on the complementary expertise of its partners that is the key to deliver the expected outcomes and business impact. The partnership is a good mix of business and R&D partners, as well as their special expertise covers the whole production/supply chain starting from waste water expertise through algae production and use, to business modelling.

Wageningen University

University & Research centre

Wageningen University is one of the leading international universities with courses in the field of healthy food and living environment. It aims to improve the quality of life by focusing on three main themes: Health, Lifestyle & Livelihood; Food & Food Production and Living Environment.

Budapest Sewage Works Pte. Ltd.

Environment management company

The Budapest Sewage Works Ltd., as the greatest environment management company, considers its mission to lead the establishment of environment friendly technologies and developments, notably the production of biogas through its activities and apart from its wastewater collection and treatment core activities.

University of Valencia

Research & Development

“The Universitat de València’s mission is to train competent professionals at European level and encourage prestigious research with international impact contributing to the development of our society. Training and research promote UV’s tasks in the field of dissemination of science and culture, and in the reaffirmation of the democratic values of the society in general, and the Valencian society in particular.”

Contact

If You have any additional information you want to share with us, or would like to know more about the MAB 2.0 project, feel free to contact our team. We are more than happy to inform you.

- Hűvösvölgyi út 83.

- Budapest

- 1021, Hungary

- +36 (1) 275-8349

- M-F: 9 AM - 4 PM

- info@ppis.hu

Miklós Gyalai-Korpos, PhD

Innovation manager